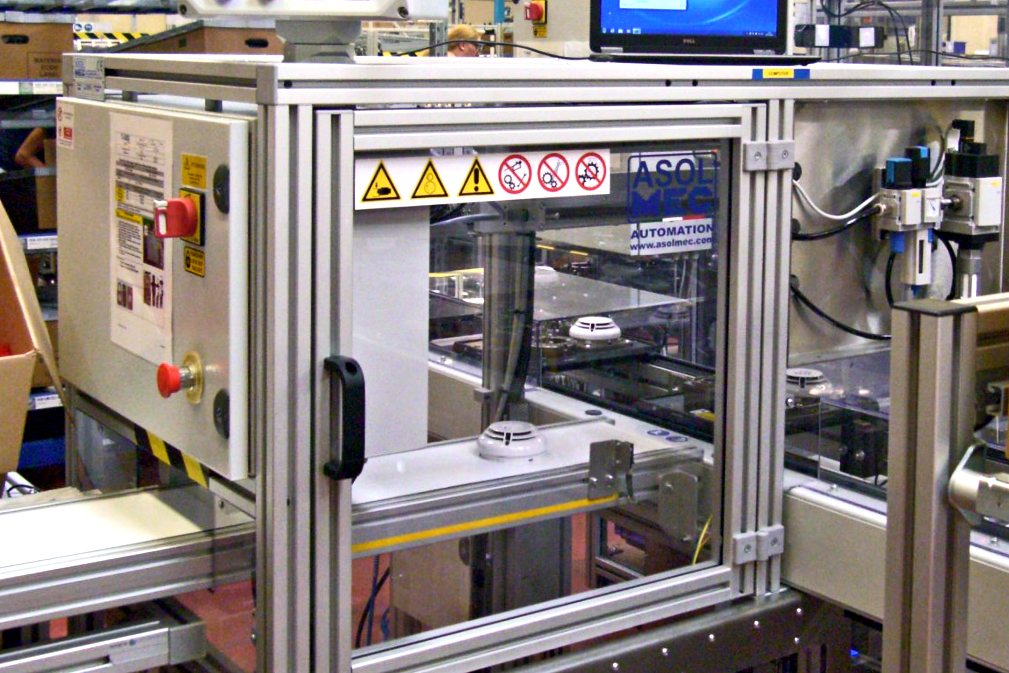

Production line makes the assembly of pivots, gears and ball bearings in plastic mechanic component. The request forecast in a maximum cycle of 6 seconds, the components position and particularly the exact number of bearing balls. The production line settles on the 0. 1% defect and is able to automatic identify all of deviations with zero margin of error.

The chosen solution includes the use of two rotatory table, for fast and precise handling of the workpieces. Components are assembled using 4 pick and place multi-headed powered by automatic loaded vibrators. An anthropomorphic robot, at the end of the cycle, provides the cardboard on several layers optimizing the positioning of the individual pieces on a compact pattern. With a second tool equipped of the same robot, places a cardboard protective layer to separate the individual layer.