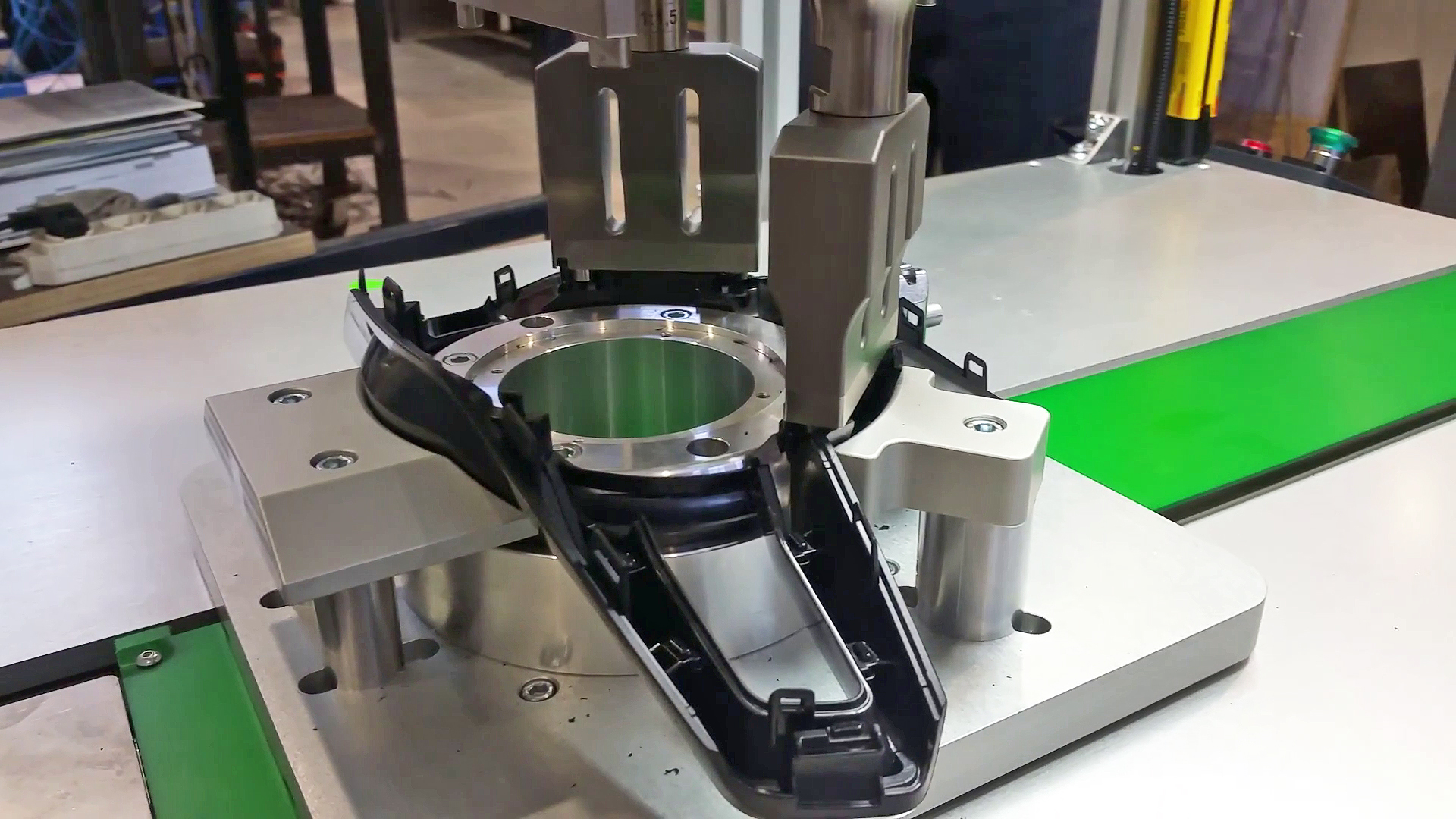

This machine hot transfers graphics from a customized film to the component being processed.

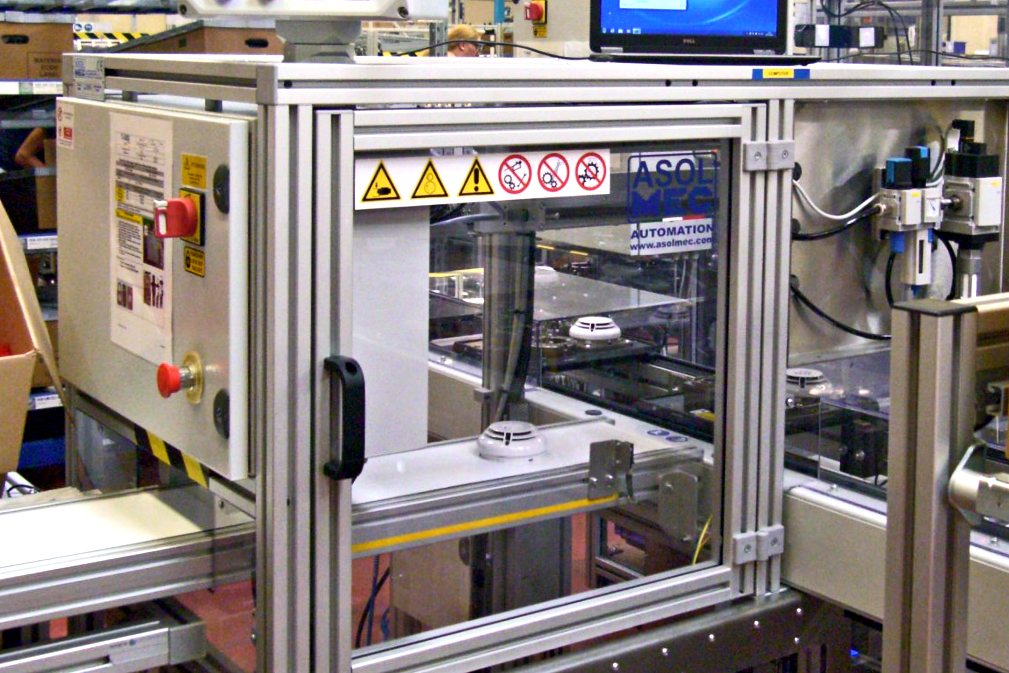

Customer needed an automatic system for heat print of their logo on variable size components, the loading had to be manual to adapt to the discontinuity of the line.

Graphic transfer process, from the film to the component, is hot carried out by means of pad, which uses a pneumatic piston that presses the film onto the component to be customized. A centring ram, ensures the consistency of the position of the final product.

The cycle time of the automatic process could be variable from 3 to 5 seconds, according to the printing surface and the temperature, for a theoretical maximum capacity of 1200 pcs/hour.